| From draft to finished product Collaboration! |

|

Together! We can create win-win situation. |

| Collaborating design a component enable you to focus on whole new project, and accelerate product developing process to time to market! These stories share you the interesting process of collaborating developing a steel strip spring. |

| |

| Application of constant force spring combine with slide rail |

|

When it comes a steel strip spring design, there are lots of factors that design engineers have to consider not only part function and mechanism design, but also including material choosing, parts connection mounting methods and dimensions in detail.

Do you have experience in collaboration with manufacturer to design a steel strip spring which is one of components insides mechanism of your new product? Collaborating design a component enable you to focus on whole new project, and accelerate product developing process to time to market! The story below would share you the interesting process of collaborating developing a steel strip spring |

|

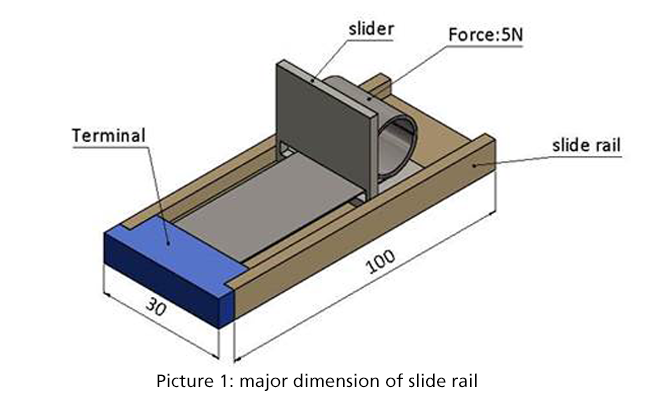

In this case, the customer just sent us this drawing (pic.1) in the beginning of project. It is a slide rail, the constant force spring play a rule of keeping the slider against the terminal. While an external force push on the slider, the spring will press against the slider to hold the position.

It is only a schematic diagram which indicates the major dimensions but not the details of the exactly way of how to connect each parts. Ming Tai based on the major dimensions to design in detail, including the parts material choosing, parts connection methods and dimensions in detail. Furthermore, we run a feasibility analysis to ensure the function to meet customer’s need.

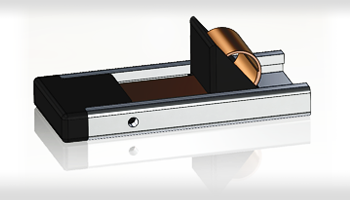

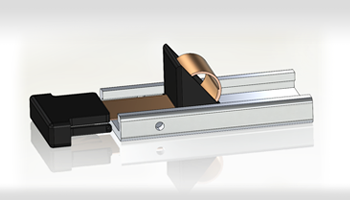

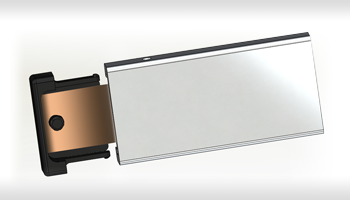

After we know all the details of the product, we start to process with the drawing. We will draw 3D drawings which illustrate the final design of the slide rail. Customers can know the details of how the slider and the bottom plate connected and how the spring connect with the terminal (pic.4). |

|

|

|

| Picture 2: final design of slide rail in detail |

|

| Picture 3: details of terminal structure |

|

| Picture 4: The method of connection of spring and terminal |

|

|

|

When the drawing was approval by the customer, we started to manufacture, test and assembly. Ming Tai commit ourselves to control the best quality of all the components of the spring set.

The picture below (pic.5) is the finished product of the slide rail with constant force spring.

Picture 5 : slide rail with constant force spring

|

| From spring set initial design phase to production and final assembly, customers collaborate with Ming Tai enable them to gain lots of benefits. |

1. Saving time for product developing

2. Find out the optimized solution beyond your expectation

3. The best quality of product

4. having best support and service to fulfill customer’s needs. |

| Having a new project in hand? You are welcome to give us a try, we would try our best to help you and give you the best technical support! |

|

|

| |

|