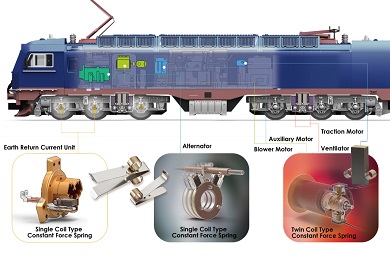

| In rail vehicle, constant force springs designed for carbon brushes can be applied to alternators; auxiliary motor, blower motor, traction motor, slip ring and earth return current units. |

|

|

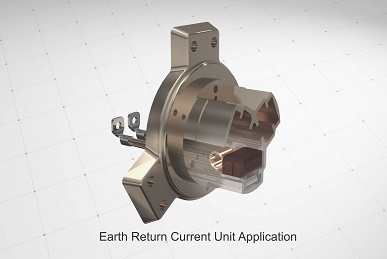

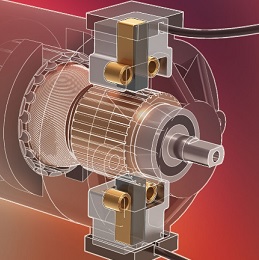

Constant force springs ensure that the carbon brush works consistently by dependably exerting constant pressure to increase brush life and to reduce electrical wear. Carbon brushes can also be used for earth return current units to divert static and induced electric currents in a motor shaft away from the bearings, and to protect them from pitting and damage.

Constant force spring keeps carbon brush to rub against the outside wall of a rotating slip ring. As the metal ring turns, the electrical current or signal is conducted through the brush to the metal ring making the connection.

|

|

| |

| All Applications of Constant Force Spring in Railway Vehicle |

|

|

Railway vehicles generally use carbon brushes for DC motors, starters, alternator, blower motor, traction motor, and earth return current units.

Grounding contacts are devices that transfer the electrical from static to the rotating parts, which is from bogie to the wheel in train system. The spring presses the brush against the wheel shaft to make electrical contact. The current is transferred from the brushes to the ground. It aims to ensure that the electrical circuit from the catenary to the wheels to the rails is closed.

The benefits of adapting constant force spring in the above devices are good mechanical stability, low friction coefficient as well as effectively protecting bearing from damage. Thanks to character of constant output force of our constant force spring.

A small constant force spring play a big role of ensuring reliable electric current transfer in railway traffic.

|

|

|